|

The Industrial Safety and Health Law stipulates that the employer shall, when a worker is to be placed in the dangerous or harmful operations provided for by the Ordinance of the Ministry of Health, Labor and Welfare, give the worker the special education for safety and/or health concerning the said operations, as provided for by the Ordinance of the Ministry of Health, Labor and Welfare.

(Article 59 3.)

Rules on Special Education for Safety and Health stipulates that the special education pertaining to the work shall be conducted by eight hours or longer academic education and practical education.

(Excerpts of summary in Article 3) |

■Lecture subjects of cutting

Relevant laws and regulations

The trainee learns about Industrial Safety and Health Law (summary) and Rules on Special Education for Safety and Health (summary).

Type and structure of safety device

The trainee learns about the two-hand operation method, beam type, safety device selection key, and other types and functions of the safety device.

Pre-work inspection

The trainee learns about the inspection in stoppage and function test, and remedies to be taken if a fault is found.

Safety hints on cutting work

The trainee learns about the safety standards of the job site and general safety hints while checking various factors that can cause accidents and disasters.

Cutting work

The trainee learns about the work standard, holding pressure, angle of the cutting edge and so on. |

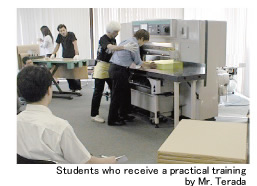

■Practical training subjects of cutting

Cutting maintenance

The trainee learns about adjustment of the backgauge angle and actual size as well as safe operation of the cutting machine.

Knowledge about paper

Shape of paper, measurement standards (rhombus, length, curl, waving, edge abrasion) and changes caused by circumstances such as humidity. The trainee also learns about the resistance between the paper and knife.

Cutting technology

The trainee learns about end stopper cutting, end cutting, feed cutting and other various cutting methods as well as the probable causes and remedies of cutting trouble phenomena.

Paper handling technique

The trainee learns about opening and stacking techniques and handling methods such as lifting and carrying. |